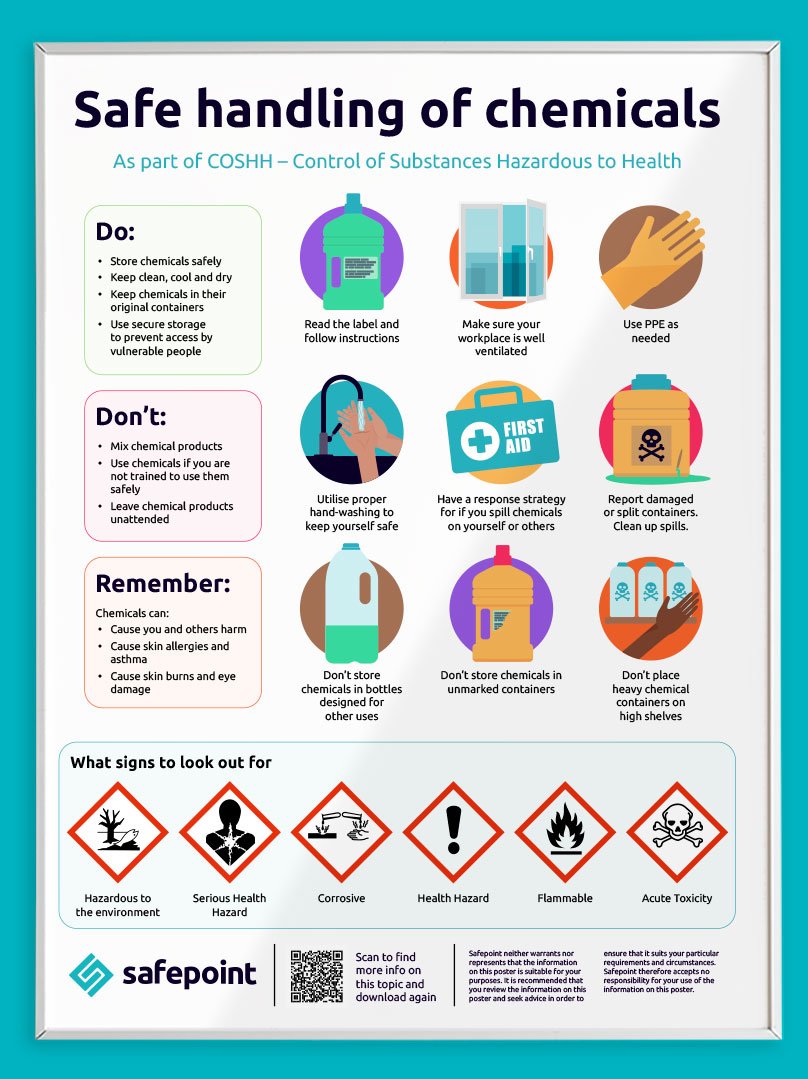

What is COSHH? With FREE "Safe handling of chemicals" poster!

Download your free “Safe handling of chemicals” poster

A simple introduction to COSHH

COSHH stands for the “Control of Substances Hazardous to Health”. COSHH laws tell employers how they should handle and manage dangerous substances, such as poisons, corrosive materials and flammable products.

Substances covered by COSHH laws may be:

Immediately hazardous (for instance through burning the skin)

Hazardous over a long time (such as fumes that can cause lung damage)

And/or hazardous to the environment.

What is the point of COSHH?

Like many health and safety laws and regulations, COSHH is in place to protect workers –and the public– from immediate or longterm harm.

Understanding COSHH is important for employers –as they have a duty of care over their team and can make structural changes– but also for employees.

Employees should have an understanding of their rights and best practices, and should should be comfortable speaking up when they need better protections. I.e, if an employee is asked to handle hazardous chemicals, they should be provided the correct training and PPE and should be comfortable asking for more support if they need it.

What are examples of substances hazardous to health?

The definition of a hazardous substance is largely in the name but, for convenience, the Health and Safety Executive has helpfully laid out a list of examples:

Chemicals and products containing chemicals

Fumes

Dusts

Vapours and mists

nanotechnology

gases and asphyxiating gases

biological agents (germs). If the packaging has any of the hazard symbols then it is classed as a hazardous substance.

germs that cause diseases such as leptospirosis or legionnaires disease and germs used in laboratories.

Note that lead, asbestos and radioactive substances are covered by their own regulations so aren’t covered in COSHH.

Does COSHH apply to the self-employed?

In short, yes, COSHH applies to self-employed workers.

If you have employees of any kind, COSHH applies.

If you have no employees but you “take hazardous substances to other people’s premises”, then all areas of COSHH apply, apart from ones relating to monitoring and surveilling health.

How to meet COSHH standards and keep your staff safe

Download your free “Safe handling of chemicals” poster

We won’t go into every aspect of COSHH as there are many standards and caveats that differ depending on your role and sector. For a more in depth look, we highly recommend visiting the HSE.

We will, however, offer some general recommendations on how you should approach your control of hazardous substances.

The Hierarchy of controls

If you meet a health and safety expert at a dinner party and –for some reason– want them to talk at length about their job, a good place to start would be the hierarchy of controls.

The hierarchy of controls is really worthwhile for anyone thinking about their health and safety needs but, for this article, you only need to know the basics.

Essentially, the hierarchy of controls promotes removing and substituting hazards at the source, before resorting to reactionary protections, like PPE. The “hierarchy” aspect comes from the notion that you should deal with the hazard “stop hurling bricks” before offering protection “giving everyone hard hats”.

Principles of good control practice

Instead of using the more ubiquitous hierarchy of controls, COSHH uses a different –but similar– system called the “Principles of good control practice” (which sounds like an Enigma B-side).

Unlike the hierarchy of controls, the principles of good control practice are not listed in order –instead they should all be considered at the same time. The principles are:

1. Minimise emission, release and spread

In essence, this says that it is better to lessen the amount of hazardous material you put out, rather than to just put more effort into removing it. Think of it like trying to avoid making a mess, so you have less to clean up.

Once you have attempted to lessen the amount of hazardous material emitted, you should further minimise how much people are exposed to it, by proper containment, and then proper ventilation.

2. Consider routes of exposure

Exposure to harmful materials can happen through ingestion, skin or inhalation. In order to lower the risks, you need to consider how the contaminate will be exposed.

As a simple example, if something is only dangerous when breathed in, then gloves might not be necessary, but a mask might be.

3. Choose control measure proportionate to the risk

In a nutshell, this means that more dangerous materials require more serious controls. Simple!

4. Choose effective control options

Consider the effectiveness and reliability of a solution before rushing to implement it. Here, it is good to consider the hierarchy of control mentioned earlier, and apply the most robust solutions first.

That means that, eliminating or substituting a hazard may be more effective and reliable than, for example, just adding extra layers of PPE (more on that next!).

5. Personal Protective Equipment (PPE)

Personal protective equipment (gloves, masks, protective overalls, etc.) should be seen as a last resort, and often may be used as an addition to other safety precautions.

That’s not to say that effective, appropriate, and well-fitting PPE isn’t valuable, but you should consider all other options first.

And, again, sometimes the answer is “all of the above”. It might be that –after you have swapped to a less dangerous material, provided some serious ventilation, and assessed every aspect of your control options– you will still have to dress your employee like Homer Simpson handling uranium.

Download a free Risk Assessment template

Risk assessments

Unsurprisingly, the use of “substances hazardous to health” should very much be seen as a risk. As such, organisations that use these substances should build them into their risk assessments.

If you are new to risk assessments, we have a great (and totally free) risk assessment template for you to download.

If you’re assessing the risk of handling hazardous substances, we suggest you also use the “Principles of good control practice” above to help you.

Safe handling of chemicals

Now that we’ve got the theoretical stuff out the way, we’d like to offer some practical advice on storing and using chemicals. All this advice is taken from the HSE, and can be found on our handy free poster.

Dos:

Store chemicals safely

Keep clean, cool and dry

Use secure storage to prevent access by vulnerable people

Read the label and follow instructions

Make sure your workplace is well ventilated

Use PPE as needed

Utilise proper hand-washing to keep yourself safe

Have a response strategy for if you spill chemicals on yourself or others

Report damaged or split containers. Clean up spills.

Don’ts:

Don’t mix chemical products

Don’t use chemicals if you are not trained to use them safely

Don’t leave chemical products unattended

Don’t store chemicals in bottles designed for other uses

Don’t store chemicals in unmarked containers

Don’t place heavy chemical containers on high shelves

And remember, chemicals can:

Cause you and others harm

Cause skin allergies and asthma

Cause skin burns and eye damage

Download your free “Safe handling of chemicals” poster